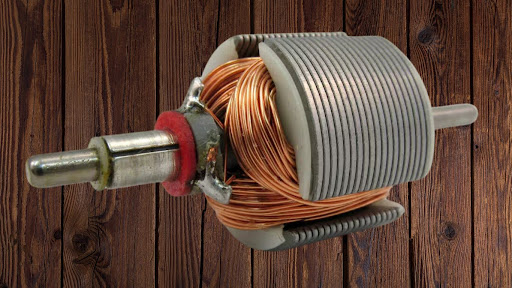

In the cutting edge auto industry, the interest for accuracy and elite execution electric engines has risen altogether, especially with the developing movement toward electric and half breed vehicles. A vital part in these engines is the armature, a urgent component that assumes a focal part in changing over electrical energy into mechanical energy. The most common way of winding the armature is fundamental, and the development of armature winding machine has been instrumental in fulfilling the business’ rising needs for speed, accuracy, and productivity.

The Importance of Armature Winding in Automotive Motors

Armature winding is the cycle wherein wire is twisted around the center of an armature, making the electromagnetic field expected for engine activity. The quality and consistency of the twisting straightforwardly influence the engine’s productivity, power result, and life expectancy. Before, this interaction was performed physically by talented specialists, yet as the auto area advanced, the requirement for more predictable, quicker, and financially savvy techniques prompted the improvement of machines planned explicitly for armature winding.

Transition from Manual to Automated Winding

At first, armature winding was a work escalated process, depending on human mastery to guarantee that the wire was twisted accurately around the center. While gifted administrators could accomplish an elevated degree of accuracy, the cycle was slow and frequently inclined to human mistake. With the quick development of the car business, especially in the domain of electric vehicles, makers looked for quicker, more exact techniques for delivering armatures in huge amounts.

The Advent of the Automatic Armature Winding Machine

The following critical progression in armature winding innovation accompanied the advancement of the automatic armature winding machine. These machines reformed the interaction by completely computerizing the winding cycle. automatic machines are equipped for playing out different twisting activities without the requirement for human intercession, essentially speeding up and consistency.

The Role of Honest Automation in Improving Efficiency

As the auto area keeps on advancing, the requirement for much more modern and productive armature winding machines has driven the improvement of cutting edge mechanization arrangements. Organizations spend significant time in mechanization have coordinated state of the art advances to upgrade the presentation of armature winding machines. One such area of progress is the utilization of honest automation advancements, which center around improving the assembling system through shrewd frameworks.

Increased Demand for Customization and Flexibility

As electric vehicle innovation progresses, the car business is seeing an expanded interest for specific engines intended for various execution needs. This has prompted a more noteworthy accentuation on customization in armature winding. Present day automatic armature winding machines are intended to oblige a large number of engine types, for certain machines offering adaptability in both the winding system and the center shape. The capacity to adapt to various plans and details is fundamental as producers endeavor to meet the changing prerequisites of EVs, from little metropolitan vehicles to superior execution sports models.

The Future of Armature Winding Machines in the Automotive Sector

The fate of armature winding machines looks encouraging, with progressing headways in computerization and brilliant innovation. As electric vehicles become more standard and the interest for superior execution engines expands, these machines will keep on advancing, turning out to be significantly more productive, exact, and versatile.

The Role of Honest Automation

The idea of honest automation in the auto business underscores making straightforward and solid frameworks that improve efficiency without compromising quality. automatic armature winding machines epitomize this standard via consistently coordinating with other assembling frameworks, for example, mechanical sequential construction systems and ongoing observing programming.

These machines likewise line up with maintainability objectives. By lessening energy utilization and material waste, they add to greener assembling rehearses, a vital concentration as the business shifts towards electric and crossover vehicles.

The Future of Armature Winding Machines in the Automotive Sector

As the car business advances, so too will the innovation behind armature winding machines. A few expected patterns include:

Artificial Intelligence Integration

Simulated intelligence driven armature winding machines could foresee upkeep needs, streamline creation plans, and further work on winding exactness.

Smart Factory Connectivity

With Industry 4.0 standards, armature winding machines will coordinate into brilliant industrial facilities, empowering information driven independent direction and improved functional proficiency.

Smart Factory Connectivity

The ascent of EVs has expanded the interest for cutting edge engines. Future armature winding machines will take care of particular engine plans expected for these vehicles.

Conclusion

The advancement of armature twisting machines in the car area exhibits the business’ capacity to adjust and develop. From manual cycles to complex automatic armature winding machines, the excursion mirrors a promise to effectiveness, accuracy, and maintainability. By embracing honest automation, makers are further developing efficiency as well as setting new principles for quality and ecological obligation.