In the electric engine industry, the assembling system assumes an essential part in guaranteeing the proficiency and dependability of the end result. Quite possibly of the most basic move toward engine gathering is armature winding, which is principal to the engine’s activity. The armature winding cycle includes folding wire over the armature center to make an attractive field, an interaction that impacts the exhibition, productivity, and life expectancy of the engine. Armature winding machines have turned into a crucial apparatus in the creation of electric engines.

What is an Armature Winding Machine?

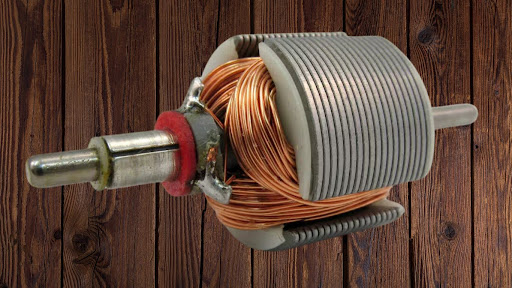

An armature winding machine is a particular gadget used to breeze wire around the armature center of an electric engine. The armature comprises of a rotor that twists inside the engine to create mechanical energy. The twisting of copper wire around the armature is fundamental to make the essential electromagnetic field for the engine to work. The armature winding machine guarantees that this interaction is finished with accuracy, consistency, and speed.

Types of Armature Winding Machines

The armature winding machine has developed after some time, with headways prompting different sorts of machines intended to address explicit issues in the assembling system. The most well-known types include:

Automatic Armature Winding Machines

As interest for higher efficiency and accuracy has expanded, automatic armature winding machines have arisen as an important resource for producers. These machines work independently, playing out the twisting system with insignificant human intercession. Computerization takes into consideration quicker creation times, decreased blunders, and a more elevated level of consistency across various units.

Fully Automatic Armature Winding Machines

A higher degree of computerization is found in completely automatic armature winding machines. These machines are intended to perform the twisting system as well as other fundamental errands, for example, embedding the injury armature into the engine gathering, testing the finished parts, and now and again in any event, bundling. The presentation of completely automatic frameworks has essentially diminished work costs and worked on generally speaking efficiency in engine fabricating plants.

Advantages of Armature Winding Machines in the Electric Motor Industry

Increased Efficiency

One of the essential advantages of utilizing an armature winding machine is the lift in productivity it gives. Manual winding is a tedious cycle, and with robotization, the winding machine can work ceaselessly without weakness, bringing about a quicker and more reliable result.

Improved Quality Control

Accuracy is fundamental in armature twisting to guarantee ideal engine execution. Armature winding machines, particularly automatic variants, offer exact command over the winding system, decreasing the opportunity of human mistake. This consistency prompts better quality engines with less deformities and lower dismissal rates.

Cost Savings

However there is an underlying interest in buying a automatic or completely automatic armature winding machine, the drawn out reserve funds are impressive. These machines lessen work costs and limit the potential for exorbitant slip-ups, prompting more productive tasks.

Flexibility

Present day armature winding machines can be acclimated to deal with various sizes and sorts of armatures, making them profoundly adaptable for makers that need to create different electric engines.

Factors Affecting Fully Automatic Armature Winding Machine Price

While considering the acquisition of a completely automatic armature winding machine, a few elements add to the cost:

Level of Automation

Completely automatic armature winding machines offer high level robotization, and that implies that the more elements a machine has, (for example, reconciliation with different cycles like testing and bundling), the higher the cost.

Machine Capacity

Machines that can deal with bigger volumes or take care of high velocity creation lines will generally be more costly because of their upgraded abilities.

Technology and Features

The further developed the innovation (like easy to use interfaces, keen programming for mistake identification, and constant execution observing), the higher the expense.

Customization

Exceptionally constructed machines custom-made to explicit creation needs, for example, winding complex shapes or dealing with uncommon armature sizes, may likewise come at a greater cost.

While the fully automatic armature winding machine price might appear to be critical, the drawn out benefits as far as diminished work costs, less imperfections, and expanded creation productivity frequently offset the underlying venture.

FAQs about Armature Winding Machines

What is the main function of an armature winding machine?

The essential capability of an armature winding machine is to wind copper wire around the armature center in electric engines. This interaction creates the vital electromagnetic field for engine activity.

How does an automatic armature winding machine differ from a manual one?

Dissimilar to manual winding, a automatic armature winding machine plays out the whole twisting interaction with negligible human intercession, further developing rate, exactness, and consistency.

Can a fully automatic armature winding machine handle different sizes of armatures?

Indeed, numerous cutting edge armature winding machines are planned with flexible elements to deal with an assortment of armature sizes, making them flexible for various engine types.

How much does a fully automatic armature winding machine cost?

The cost of a completely automatic armature winding machine changes relying upon highlights, limit, and customization. Normally, these machines are more costly than manual ones because of their cutting edge innovation and computerization. Notwithstanding, the expense is many times legitimized by the higher efficiency and decreased work costs.

End

Armature winding machines are urgent in the electric engine fabricating industry. Whether automatic or completely automatic, these machines smooth out the creation interaction, guaranteeing that engines are delivered with high accuracy and proficiency. However the interest in such hardware can be significant, the drawn out benefits with regards to cost reserve funds and item quality settle on them a shrewd decision for some producers. As the business keeps on advancing, armature winding machines will stay a fundamental apparatus for satisfying the developing needs for great electric engines.