Tranny tubes, essential yet often overlooked components, play a crucial role in the seamless operation of automotive transmission systems. By facilitating efficient fluid transfer and preventing overheating, they ensure your vehicle’s gearbox runs smoothly under various conditions. This article delves into the world of tranny tubes, exploring their evolution, types, and materials, and offering practical advice on selection, maintenance, and usage.

Whether you’re a car enthusiast seeking to enhance performance or a novice aiming to understand your vehicle better, our comprehensive guide demystifies tranny tubes and arms you with the knowledge to choose the best one for your needs. Join us as we navigate through the intricacies of tranny tubes, highlighting their significance in automotive innovation and maintenance.

The Evolution of Tranny Tubes

The history of tranny tubes is a testament to the remarkable advancements in automotive technology. Originally simple conduits for fluid transfer within transmission systems, tranny tubes have evolved significantly, paralleling the broader evolution of vehicles themselves.

From Basics to Complex Systems

In the early days of automotive engineering, tranny tubes were rudimentary, designed merely to contain and channel transmission fluid. However, as vehicles became more complex and powerful, the demand for more efficient and durable tranny tubes grew. This necessity spurred innovation, leading to the development of tubes capable of withstanding higher pressures, temperatures, and corrosive environments.

The Rise of Amateur Radio and Its Influence

Interestingly, the rise of amateur radio in the early 20th century played an unexpected role in the evolution of tranny tubes. Amateur radio enthusiasts, experimenting with various materials and designs for better signal transmission, indirectly contributed to the knowledge pool regarding conductive materials and insulation. This knowledge was later applied in the automotive industry, leading to the development of tranny tubes with improved electrical insulation properties, essential for reducing interference in increasingly electronic-based vehicle control systems.

Transition to Transistors and Material Innovation

The transition to transistors in the mid-20th century marked a significant leap in electronic engineering, influencing automotive design and, consequently, tranny tube development. With vehicles incorporating more electronic components, the need for tranny tubes that could protect against electromagnetic interference while ensuring reliable fluid transfer became paramount. This period saw the introduction of advanced materials, including synthetic rubbers and plastics, which offered superior durability, flexibility, and resistance to chemicals and heat.

Improved Designs and Growing Demand

As automotive technology continued to advance, so did tranny tube designs. The introduction of automatic transmissions and the increasing power outputs of engines required tubes that could handle more complex routing and higher thermal loads. Manufacturers began to experiment with alloys, composite materials, and multi-layer constructions to meet these demands. Stainless steel, known for its corrosion resistance and strength, became a popular choice for high-performance applications. Similarly, the use of butyl rubber and polyvinyl chloride (PVC) in tranny tubes offered improvements in flexibility and chemical resistance, making them suitable for a wide range of vehicles.

The Current Landscape

Today, tranny tubes are more sophisticated than ever, incorporating materials like polytetrafluoroethylene (PTFE) and high-grade polymers that offer unmatched performance across extreme conditions. The emphasis on durability, efficiency, and compatibility with a range of fluids has led to tranny tubes that significantly enhance vehicle reliability and longevity. Furthermore, environmental considerations have pushed for the development of eco-friendly materials and designs that minimize waste and improve recyclability.

The evolution of tranny tubes from simple fluid conveyors to complex components integral to vehicle performance and reliability mirrors the broader trajectory of automotive innovation. As we look towards the future, the ongoing pursuit of efficiency, durability, and environmental sustainability promises to drive further advancements in tranny tube technology, ensuring they remain a critical component in the automotive landscape.

Understanding the Types and Materials of Tranny Tubes

Tranny tubes, pivotal in ensuring the efficient operation of transmission systems, come in a variety of types and materials. Each type is tailored to specific needs, ranging from basic fluid transfer to advanced performance requirements. This section explores the diverse world of tranny tubes, shedding light on their materials and applications to help you make an informed choice.

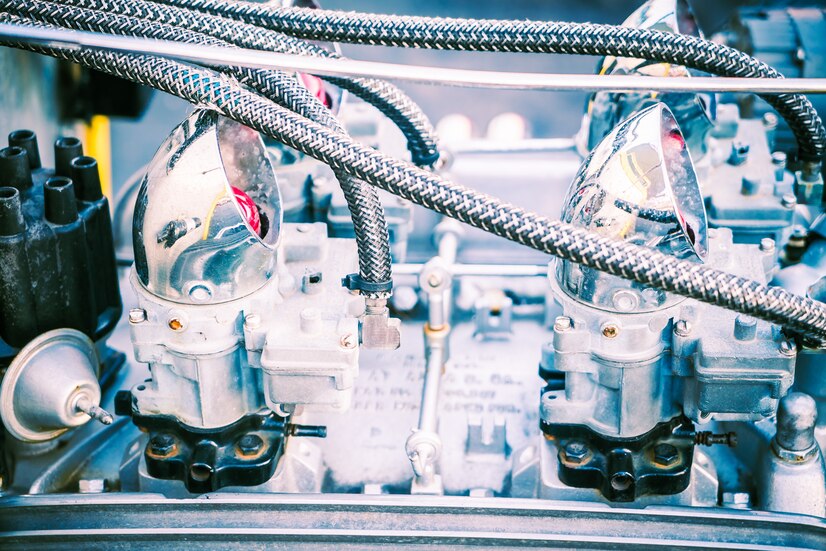

Stainless Steel Tranny Tubes

Stainless steel tranny tubes represent the pinnacle of durability and corrosion resistance. Ideal for harsh conditions, these tubes are often used in high-performance and heavy-duty vehicles where reliability is paramount. The material’s strength ensures longevity, while its resistance to heat and chemicals prevents degradation over time. Stainless steel tubes are a top choice for those seeking minimal maintenance and maximum performance.

Butyl Rubber Tranny Tubes

Butyl rubber, known for its excellent sealing properties and air retention, is another popular material for tranny tubes. This synthetic rubber offers great flexibility, making it easier to install and route through tight spaces within a vehicle’s undercarriage. Its resistance to heat, abrasions, and various chemicals makes butyl rubber tubes a versatile option for a wide range of automotive applications.

Aluminum and Copper Tranny Tubes

Aluminum and copper tubes are valued for their exceptional thermal conductivity, which helps in the efficient dissipation of heat from the transmission fluid. While not as durable as stainless steel under physical stress, these materials are lighter and contribute to overall vehicle weight reduction, a critical factor in performance and fuel efficiency. Copper tubes, though less common due to their higher cost and susceptibility to corrosion, are sometimes used for their superior heat transfer capabilities.

Plastic and PVC Tranny Tubes

In recent years, plastic and PVC have emerged as cost-effective materials for tranny tubes. These polymers offer excellent corrosion resistance, a lightweight profile, and flexibility in design. Although not as durable as metal options under extreme conditions, plastic and PVC tubes are suitable for standard vehicles and offer a compromise between performance and cost. Their adaptability to various shapes and configurations allows for customized solutions in complex automotive layouts.

PTFE and Advanced Synthetic Materials

Polytetrafluoroethylene (PTFE) and other advanced synthetic materials are at the forefront of tranny tube innovation. PTFE, in particular, is renowned for its near-universal chemical resistance, high-temperature tolerance, and minimal friction properties. These characteristics make PTFE tubes ideal for high-performance applications where reliability and efficiency are critical. Synthetic materials continue to evolve, offering new possibilities in tranny tube design and application.

Choosing the Right Material

The selection of tranny tube material should be guided by several factors:

- Durability and Resistance: Consider the operating environment and the types of chemicals or temperatures the tube will be exposed to.

- Flexibility and Installation: Evaluate the ease of installation and the need for flexibility in routing through the vehicle.

- Performance Requirements: High-performance vehicles may require materials with superior heat dissipation or chemical resistance.

- Cost and Maintenance: Balance the upfront cost against the expected lifespan and maintenance needs.

Understanding the types and materials of tranny tubes is essential for optimizing the performance and reliability of your vehicle’s transmission system. Whether you’re maintaining a classic car, outfitting a high-performance vehicle, or simply ensuring your daily driver runs smoothly, selecting the right tranny tube can make a significant difference.

Car Tranny Tubes: Function and Importance

In the intricate world of automotive mechanics, car tranny tubes play a pivotal role, albeit often unnoticed by the casual observer. These components are crucial for the smooth operation and longevity of a vehicle’s transmission system. Understanding their function and importance sheds light on how vital they are to a car’s overall health and performance.

The Core Function of Car Tranny Tubes

Car tranny tubes are primarily designed for the transfer of transmission fluid within the vehicle’s transmission system. This fluid is essential for lubricating the moving parts inside the transmission, reducing friction, and preventing wear and tear. Furthermore, the transmission fluid serves a critical role in cooling the transmission by dissipating heat generated during operation.

The tranny tube’s role extends beyond mere fluid transfer; it acts as a protective conduit that shields the fluid from contaminants and external damage, ensuring its purity and efficacy. This protection is vital for maintaining the fluid’s properties and, by extension, the transmission’s performance over time.

Importance in Vehicle Operation

- Lubrication: The smooth operation of a car’s transmission is heavily reliant on the constant flow of transmission fluid provided by the tranny tubes. Adequate lubrication minimizes the risk of overheating and mechanical wear, thereby extending the lifespan of the transmission components.

- Cooling: By facilitating the flow of transmission fluid, tranny tubes play a direct role in the cooling process. This is essential for preventing overheating, a common cause of transmission failure. Effective cooling maintains the transmission system’s efficiency and reliability, especially under heavy usage or in high-temperature environments.

- Performance and Efficiency: The condition and quality of tranny tubes can significantly impact a vehicle’s performance. Properly functioning tubes ensure that transmission fluid is efficiently circulated, leading to smoother gear shifts and optimal power transmission from the engine to the wheels. This not only enhances the driving experience but also contributes to better fuel economy.

- Protection Against Contaminants: Tranny tubes also act as a barrier against external contaminants such as dirt, debris, and moisture. Keeping these contaminants out of the transmission system is crucial for preserving the quality of the transmission fluid and preventing blockages or corrosion within the system.

The Consequences of Neglect

Neglecting the condition of car tranny tubes can lead to several issues, including leaks, blockages, and contamination of the transmission fluid. Such problems can diminish the transmission’s efficiency, result in rough shifting, and, in severe cases, cause transmission failure. Regular inspections and maintenance are essential to identify and address any issues with tranny tubes before they escalate into more significant problems.

Comprehensive Guide to Tranny Tube Varieties

The automotive world is rich with diverse components that cater to various needs and specifications, and tranny tubes are no exception. With an array of types available, selecting the right tranny tube for your vehicle involves understanding the differences and applications of each variety. This section provides a detailed overview of standard, high-performance, and custom tranny tubes, offering insights into their uses and benefits.

Standard Tubes

Standard tranny tubes are designed for everyday vehicles and applications where the transmission system operates under normal conditions. These tubes are typically made from materials like rubber or plastic, which offer a balance between durability, flexibility, and cost-effectiveness. Standard tubes are adequate for most passenger cars, providing the necessary functionality for fluid transfer and protection without the need for advanced materials or designs.

Uses: Ideal for daily driving and moderate conditions, standard tranny tubes ensure efficient fluid circulation and cooling in regular passenger vehicles.

Benefits: The primary advantage of standard tranny tubes lies in their affordability and general suitability for average driving conditions. They are widely available and can be easily replaced or maintained.

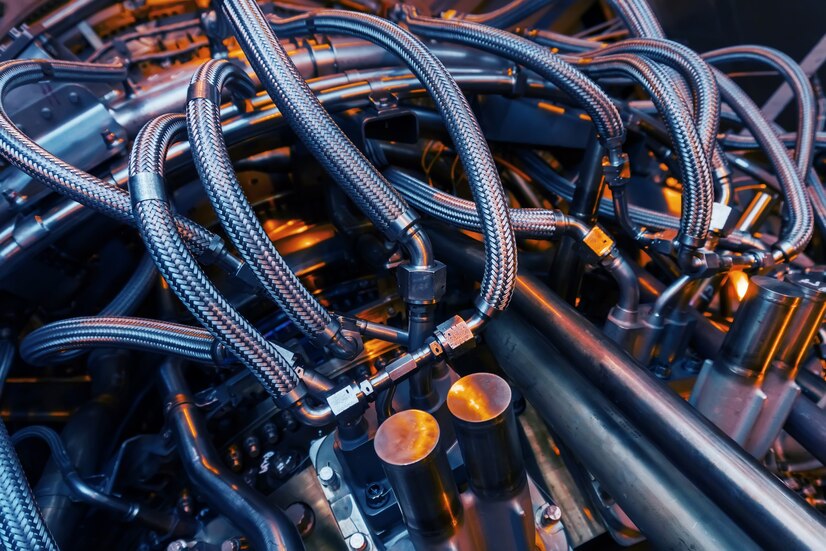

High-performance Tubes

High-performance tranny tubes are engineered for vehicles that are subjected to extreme conditions, such as racing cars or heavy-duty trucks. These tubes are often made from more robust materials like stainless steel or reinforced synthetic rubbers, capable of withstanding higher temperatures and pressures. High-performance tubes may also feature specialized designs, such as braided covers, to offer additional protection and durability.

Uses: Essential for racing, towing, and other high-stress applications, high-performance tranny tubes provide enhanced reliability and performance under severe operating conditions.

Benefits: The key benefits include superior heat resistance, increased durability, and the ability to maintain optimal fluid flow and cooling even in demanding environments. These tubes are designed to prevent failures and prolong the life of the transmission system.

Custom Tubes

Custom tranny tubes cater to specific needs or configurations that standard or high-performance tubes might not adequately address. These tubes can be custom-fabricated from a variety of materials and designs to fit unique applications, such as vintage cars, custom builds, or vehicles with modified transmission systems.

Uses: Custom tubes are ideal for vehicles that require a specific fit or enhanced performance characteristics that off-the-shelf options cannot provide. They are particularly useful for restoration projects or heavily modified vehicles.

Benefits: The primary advantage of custom tranny tubes is their ability to meet the exact specifications and requirements of any vehicle or application. This customization ensures optimal performance and fit, addressing any unique challenges or needs a vehicle may have.

Making the Right Choice

When selecting a tranny tube, consider the vehicle’s use case, the operating conditions it will face, and the level of performance you aim to achieve. Standard tubes are sufficient for most conventional applications, while high-performance tubes are better suited for vehicles that endure rigorous conditions. Custom tubes offer a solution for those with specific needs or configurations that standard options cannot fulfill.

How to Use and Maintain Your Tranny Tube

Proper use and maintenance of your tranny tube are paramount for ensuring the longevity and efficiency of your vehicle’s transmission system. Tranny tubes serve as critical pathways for transmission fluid, playing a vital role in lubrication, cooling, and overall transmission health. This section outlines essential practices for installing, flushing, inspecting, and replacing tranny tubes, aimed at maximizing their performance and extending their service life.

Installation

- Preparation: Before installation, ensure you have the correct type and size of tranny tube for your vehicle. Clean the area around the transmission where the tube will be installed to prevent any contamination.

- Fitting: Carefully thread the tranny tube into place, avoiding any kinks or bends that could restrict fluid flow. Use the appropriate tools to secure connections without over-tightening, which could damage the tube or fittings.

- Testing: Once installed, check for leaks by running the engine and shifting through various gears. Monitor the transmission fluid level and add more if necessary, ensuring it reaches the manufacturer-recommended level.

Flushing

- Frequency: Regular flushing of the transmission fluid through the tranny tube is necessary to remove contaminants and old fluid. Consult your vehicle’s manual for the recommended flushing interval, which typically ranges between 30,000 to 60,000 miles.

- Procedure: Flushing should be performed by a professional or under expert guidance, using the correct type of transmission fluid for your vehicle. The process involves pumping out the old fluid and contaminants and then refilling with fresh fluid.

Inspections

- Regular Checks: Perform regular inspections of the tranny tube for signs of wear, damage, or leaks. Look for cracks, brittleness, or any connections that appear loose or compromised.

- Environmental Factors: Consider the impact of your driving environment on the tranny tube. Extreme temperatures, road salt, and debris can accelerate wear, necessitating more frequent inspections.

Replacement

- Signs of Failure: Indicators that a tranny tube needs replacing include visible damage, persistent leaks, or a decrease in transmission performance. Ignoring these signs can lead to transmission failure.

- Choosing a Replacement: When selecting a new tranny tube, consider the demands of your vehicle’s operation. High-performance or custom tubes may be appropriate for vehicles subjected to harsh conditions or specialized use.

- Professional Installation: Given the importance of a properly functioning tranny tube, consider having replacements installed by a professional to ensure correct fitting and optimal performance.

Maintenance Tips

- Fluid Checks: Regularly check the transmission fluid level and condition through the tranny tube dipstick. Low or dirty fluid can indicate leaks or the need for a flush.

- Fluid Flush and Replacement: Adhere to the recommended schedule for flushing and replacing your transmission fluid to prevent buildup of contaminants and ensure smooth operation.

- Regular Inspection: Incorporate tranny tube inspections into your regular vehicle maintenance routine to catch and address issues early.

Proper use and diligent maintenance of your tranny tube can significantly impact the health and longevity of your vehicle’s transmission system. By following these guidelines for installation, flushing, inspections, and replacement, you can maintain optimal transmission performance and avoid costly repairs down the line.

How to Choose the Right Tranny Tube for Your Vehicle

Selecting the right tranny tube is crucial for ensuring the optimal performance and longevity of your vehicle’s transmission system. The choice involves considering several key factors, including size, design, construction, and common issues associated with tranny tubes. This section provides a comprehensive guide to help you navigate these considerations and make an informed decision.

Size

The size of the tranny tube must match the specifications of your vehicle’s transmission system. An incorrectly sized tube can lead to improper fluid flow, resulting in inadequate lubrication and cooling of the transmission components.

- Measurements: Check your vehicle’s manual or consult with a professional to determine the required size, including the length and diameter of the tube.

- Capacity: Ensure the tube can handle the volume of transmission fluid necessary for your vehicle’s operation. Too small a tube might restrict flow, while too large a tube could lead to inefficient fluid dynamics.

Design

The design of the tranny tube should facilitate easy installation, efficient fluid transfer, and effective cooling. It also needs to accommodate the specific layout and space constraints of your vehicle’s undercarriage.

- Routing: Look for a design that matches the routing requirements of your vehicle, avoiding sharp bends or areas where the tube might be prone to damage.

- Connectors and Fittings: Ensure the tube comes with compatible connectors and fittings that provide a secure and leak-free connection to the transmission system.

Construction

The construction of the tranny tube determines its durability, resistance to wear, and ability to withstand the operating conditions of your vehicle.

- Materials: Choose a material that offers the best balance of flexibility, durability, and resistance to heat, chemicals, and abrasions. Common materials include rubber, stainless steel, and advanced polymers like PTFE.

- Reinforcement: For vehicles that operate under high stress or in harsh environments, consider tubes with additional reinforcement, such as braided stainless steel, which provides extra protection against physical and thermal damage.

Common Issues

Awareness of common issues associated with tranny tubes can guide you in selecting a more reliable and longer-lasting option.

- Leakage: Look for high-quality materials and construction that minimize the risk of leaks, a common problem that can lead to transmission damage.

- Corrosion and Wear: Choose materials that are resistant to corrosion and wear, especially if your vehicle is frequently exposed to harsh chemicals or extreme temperatures.

- Compatibility: Ensure the tranny tube is compatible with the type of transmission fluid used in your vehicle, as some materials may degrade when exposed to certain fluids.

Final Considerations

- Manufacturer Recommendations: Always consider the manufacturer’s recommendations when selecting a tranny tube. OEM (Original Equipment Manufacturer) parts are designed to meet the specific requirements of your vehicle.

- Reviews and Ratings: Research reviews and ratings from other users to gauge the performance and reliability of different tranny tube brands and models.

- Professional Advice: When in doubt, seek advice from a professional mechanic or transmission specialist. They can provide valuable insights based on experience with different vehicles and tranny tube types.

Choosing the right tranny tube is a decision that impacts the efficiency, safety, and reliability of your vehicle. By taking into account the size, design, construction, and potential issues, you can select a tranny tube that enhances your vehicle’s performance and protects your transmission system against common problems.

Benefits and Applications of Tranny Tubes

Tranny tubes play an essential role in the automotive world, far beyond their basic function of transferring transmission fluid. Their impact on vehicle performance, efficiency, and longevity is profound.

Understanding the benefits and applications of tranny tubes can help vehicle owners appreciate their significance and make informed decisions regarding their vehicle’s maintenance and performance enhancement.

Benefits of Tranny Tubes

- Enhanced Vehicle Performance: Properly functioning tranny tubes ensure smooth fluid flow, which is crucial for the efficient operation of the transmission system. This results in smoother gear shifts, better acceleration, and overall improved vehicle performance.

- Increased Durability: High-quality tranny tubes are designed to withstand harsh conditions, including high temperatures and pressures, as well as exposure to chemicals. This durability reduces the risk of leaks and failures, extending the lifespan of the transmission system.

- Improved Fuel Efficiency: Efficient transmission fluid flow helps maintain optimal transmission function, which can positively affect fuel efficiency. A smoothly operating transmission system requires less power to shift gears, thereby reducing fuel consumption.

- Protection Against Contaminants: Tranny tubes act as a barrier, protecting the transmission fluid from contaminants such as dirt, debris, and moisture. Clean transmission fluid is vital for the health of the transmission system, preventing wear and tear on its components.

- Cost Savings: Regular maintenance and the use of quality tranny tubes can prevent costly transmission repairs or replacements. By ensuring the integrity and efficiency of the transmission system, vehicle owners can save on potential future expenses.

Applications of Tranny Tubes

Tranny tubes find their applications in a wide range of scenarios, from daily driving to specialized industrial uses.

- Passenger Vehicles: In cars and SUVs, tranny tubes are crucial for the everyday operation of the transmission system, ensuring comfortable and efficient driving experiences.

- Commercial and Heavy-Duty Vehicles: Trucks, buses, and other heavy-duty vehicles rely on robust tranny tubes designed to handle higher loads and more strenuous conditions, ensuring reliability and performance in commercial operations.

- Racing and High-Performance Vehicles: In the world of racing and high-performance cars, tranny tubes must withstand extreme conditions without compromising on performance. Specialized tubes with enhanced heat resistance and durability are used to meet these demanding requirements.

- Industrial and Agricultural Machinery: Beyond automotive applications, tranny tubes are also used in industrial and agricultural machinery, where they ensure the smooth operation of transmission systems under various conditions, contributing to the efficiency and reliability of heavy equipment.

- Marine Applications: In boats and marine vehicles, tranny tubes are designed to resist corrosion from saltwater exposure, ensuring the longevity and reliability of marine transmissions.

The evolution of language and terminology is a testament to society’s growing awareness and sensitivity towards inclusivity and respect for all individuals. In recent years, the term “tranny,” historically used in automotive contexts to refer to transmission systems, has come under scrutiny due to its derogatory connotations when used to describe transgender individuals. This section delves into the shift from derogatory usage to a more empowering and respectful discourse, emphasizing the importance of language in shaping societal attitudes and the automotive community’s response.

Term Change: Derogatory to Empowering

- Historical Context: Originally, the term “tranny” was an innocuous abbreviation used within the automotive industry to refer to a vehicle’s transmission. However, as language and societal norms evolve, it’s become evident that the same term, when used to refer to transgender people, carries a derogatory and dismissive tone.

- Effect on Transgender People: The use of “tranny” in a derogatory manner contributes to the marginalization and dehumanization of transgender individuals. It perpetuates a culture of intolerance and misunderstanding, impacting the mental and emotional well-being of those it targets.

- Shift in Awareness: There has been a significant shift towards recognizing the impact of language on transgender individuals’ dignity and rights. This awareness has led to a call for change, advocating for the use of respectful and accurate terminology when referring to transgender people.

Consent and Representation in Tranny Tube Content

- Inclusive Language: The automotive community, along with broader society, is becoming more conscious of the need for inclusive and respectful language. This includes reevaluating terms that may be offensive or harmful, even if unintentionally so, in all contexts.

- Alternative Terminology: To avoid the derogatory connotations associated with “tranny,” alternatives such as “transmission tubes” or simply “transmission lines” are being adopted. These terms maintain clarity without risking offense or misunderstanding.

Future of Tranny Tubes: Challenges and Opportunities

- Educational Efforts: There is an ongoing effort to educate the automotive community and the public about the importance of respectful language. This includes understanding the historical context of terms and the impact they have on marginalized groups.

- Inclusivity in the Automotive Industry: The industry is facing a unique opportunity to lead by example in fostering an inclusive and respectful environment. This involves not only changing terminology but also supporting diversity and representation within the community itself.

- Collaboration with LGBTQ+ Advocacy Groups: Engaging with LGBTQ+ organizations and advocacy groups can provide valuable insights into respectful language use and help promote a culture of inclusivity and understanding.

Looking Forward: The Future of Tranny Tubes

The automotive industry, like many others, is at a crossroads, facing challenges and opportunities as it evolves to meet the demands of the 21st century. This is particularly true for components like tranny tubes, which, though small, play a crucial role in the overall functionality and efficiency of vehicles. As we look to the future, several trends and innovations are set to shape the development and application of tranny tubes, ensuring they continue to meet the needs of modern and future vehicles.

Emerging Designs and Material Innovations

- Advanced Materials: The quest for materials that can withstand higher temperatures, pressures, and corrosive chemicals continues. Innovations in material science, such as the development of new polymers and composite materials, offer promising avenues for creating more durable, efficient, and environmentally friendly tranny tubes.

- Smart Technologies: The integration of smart technologies into tranny tubes is on the horizon. Sensors could monitor the condition of the transmission fluid in real-time, detecting contaminants, temperature fluctuations, and wear patterns. This data could then be used to predict and prevent failures before they occur, significantly enhancing vehicle reliability.

- Eco-friendly Solutions: As environmental concerns become increasingly paramount, the automotive industry is looking for ways to reduce its footprint. This includes developing tranny tubes from sustainable materials that are recyclable or biodegradable, without compromising on performance or durability.

Growing Demand in New Markets

- Electric Vehicles (EVs): The rise of electric vehicles presents both challenges and opportunities for the development of tranny tubes. While EVs may have different transmission systems compared to traditional vehicles, the need for high-performance, durable tubes for cooling and lubrication purposes remains. Adapting tranny tubes for use in EVs will be a key area of focus.

- Global Expansion: As automotive markets expand globally, especially in emerging economies, the demand for vehicles equipped with reliable tranny tubes is set to increase. This presents an opportunity for manufacturers to innovate and adapt products to suit a variety of climates, driving conditions, and vehicle types.

Challenges and Opportunities

- Regulatory Changes: Automotive components, including tranny tubes, are subject to a wide range of regulations concerning safety, environmental standards, and performance. Keeping pace with these regulations, while continuing to innovate, presents a significant challenge but also an opportunity to lead in the development of compliant and advanced solutions.

- Supply Chain Resilience: Recent global events have highlighted the importance of resilient supply chains. For tranny tube manufacturers, this means diversifying supply sources, investing in local production capabilities, and adopting flexible manufacturing processes to quickly adapt to changing market needs.

- Customer Expectations: As consumers become more knowledgeable and concerned about the environmental and operational aspects of their vehicles, manufacturers will need to respond with tranny tubes that meet these expectations in terms of performance, sustainability, and reliability.

Conclusion

In conclusion, the journey through the world of tranny tubes has revealed their critical importance to the automotive industry, from their historical evolution and diverse types to the intricacies of maintenance and the considerations for choosing the right one. As we navigate the cultural context and look towards future innovations, it’s clear that tranny tubes are more than just components; they are a testament to the continuous advancement and adaptation of automotive technology.

Embracing new materials, designs, and the shift towards inclusivity and sustainability, the future of tranny tubes is poised to meet the demands of modern vehicles while contributing to a more efficient, reliable, and respectful automotive landscape. This comprehensive guide underscores the significance of tranny tubes in enhancing vehicle performance and highlights the automotive community’s commitment to progress and innovation for the betterment of all.

FAQs on Tranny Tubes

What is a tranny tube?

A tranny tube, or transmission tube, is a component of a vehicle’s transmission system designed to transport transmission fluid. This fluid is crucial for lubrication, cooling, and ensuring the smooth operation of the transmission.

Why are tranny tubes important?

Tranny tubes are essential for maintaining the health and efficiency of a vehicle’s transmission. They facilitate the flow of transmission fluid, which lubricates moving parts, cools the transmission, and helps to prevent overheating and wear.

How do I know if my tranny tube needs replacing?

Signs that a tranny tube may need replacing include visible damage or leaks, a decrease in transmission performance, unusual noises during gear shifts, and the presence of transmission fluid beneath the vehicle.

What are the different types of tranny tubes?

Tranny tubes come in various materials and designs, including stainless steel, rubber, aluminum, and advanced polymers like PTFE. The choice depends on the vehicle’s requirements, such as durability, flexibility, and resistance to high temperatures and chemicals.

Can I replace a tranny tube myself?

While it is possible for someone with mechanical experience to replace a tranny tube, it’s often recommended to seek professional assistance. Proper installation is crucial to avoid leaks and ensure the transmission system functions correctly.

How often should tranny tubes be inspected?

It’s advisable to inspect tranny tubes regularly, such as during routine vehicle maintenance or oil changes. Look for signs of wear, damage, or leaks. The exact frequency can depend on the vehicle’s age, usage, and driving conditions.

Are there eco-friendly options for tranny tubes?

The automotive industry is increasingly focusing on sustainability, leading to the development of tranny tubes made from recyclable or eco-friendly materials. These options aim to offer the same performance and durability as traditional materials while reducing environmental impact.

Can a faulty tranny tube affect fuel efficiency?

Yes, a faulty or inefficient tranny tube can lead to poor transmission performance, which in turn can affect the vehicle’s fuel efficiency. Ensuring that tranny tubes are in good condition helps maintain optimal fuel economy.

How do tranny tubes fit into the future of electric vehicles (EVs)?

As the automotive industry shifts towards electric vehicles, the role of tranny tubes also evolves. While EVs may have different transmission systems, the need for efficient cooling and lubrication remains, requiring adaptations in tranny tube design and material.

What steps can I take to ensure the longevity of my tranny tube?

Regular inspections, timely maintenance, and addressing any issues promptly are key to ensuring the longevity of your tranny tube. Using the correct type of transmission fluid and following the manufacturer’s recommendations for maintenance can also help extend the life of your tranny tube.